Composite vs Natural Timber Decking: What's Best?

In the past, natural timber has always been the material of choice for outdoor decking in Australia. But new composite timber products developed in recent years are starting to challenge the use of traditional wood, thanks to the many advantages they offer.

What is composite timber decking made from?

Composite timber is made from a mixture of wood fibres, plastic and various binding agents which, when combined, form a material much stronger, heavier, and denser than timber.

Both the wood and plastic used in composite timber are sourced from recycled materials, the wood fibres in the form of sawdust left over from lumber processing, and the plastics from recycled materials such as shopping bags.

The manufacture of composite decking involves a co-extrusion process where the ingredients are combined and melted together in an extruder and then forced through a ’die’ to create lumber-shaped moulds.

Two common types of plastics used in composite timber are polypropylene and polyethylene, with polyethylene being the most widely used due to its greater availability and lower recycling costs.

However polypropylene is beginning to be used more frequently, thanks to its higher melting point, which means it absorbs less heat than other plastics and is cooler underfoot. It is also stronger, which helps resist sagging between joists and improves structural integrity.

What are the benefits of composite decking?

Composite timber has a number of unique advantages, which are seeing it become increasingly popular as a decking material;

- It’s easy to install – made with grooves, the planks fit easily together with the use of hidden fixings, which improves aesthetics and reduces installation time.

- It’s safe underfoot – it doesn’t splinter, making it safe for bare feet and pets and it can also be manufactured with anti-slip properties.

- It’s very low maintenance – because it doesn’t rot, crack, warp or fade over time, composite timber needs no sanding, staining, painting or sealing, just an occasional clean with soap and water.

- It’s eco–friendly – it uses recycled materials in its manufacture which would otherwise go to waste, including industrial wood scraps and recycled plastics.

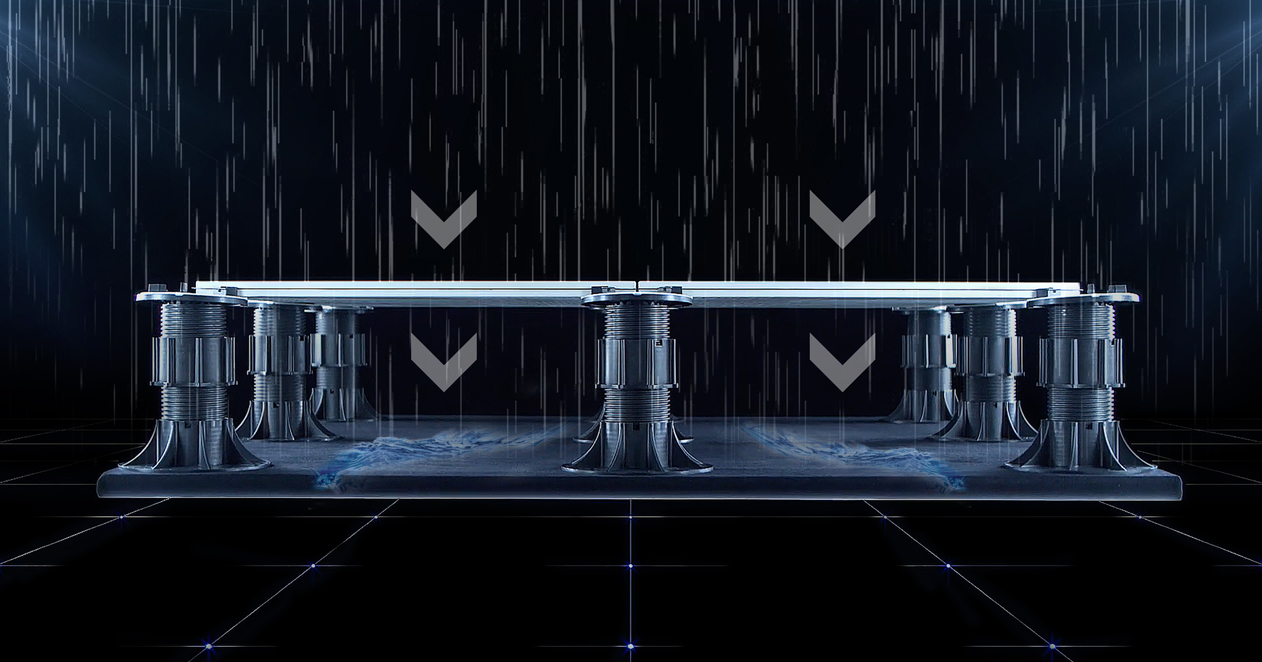

- It’s made for our Australian conditions – it’s resistant to all types of weather conditions, as well as to termites, rot, mould, pool chlorine and salt water.

- It has unlimited design potential – because composite timber is moulded, it offers greater flexibility in shape and form, without the need to compromise on performance.

- It’s highly durable and long-lasting – composite timber boards often come fully capped, with a protective layer on all four sides, making them fade-resistant, UV-resistant and resistant to ageing.

- It’s timber without the limitations – while timber varieties can vary in hardness and strength, composite timber can be made to mimic any type, colour or texture of wood, while maintaining uniform structural integrity.

7 reasons why composite timber is better than natural timber for decking

Clearly, composite timber has some very compelling advantages over traditional timber decking;

- It’s faster and easier to install.

- It’s safer underfoot.

- It’s easier to maintain.

- It uses recycled materials rather than harvested trees.

- It’s resistant to weathering, rotting, mould and termites.

- It can be moulded into non-traditional forms.

- It has the aesthetics of wood without the disadvantages.

In fact, the only possible negative that could be attributed to composite timber is that it’s more expensive to buy than natural timber decking. But even that, is not actually a drawback, because while it may cost more initially, it will pay for itself many times over with the savings in maintenance and repairs that must be regularly carried out on natural timber decking.

Get in touch with KEKSIÄ for composite decking

Like to see the benefits of composite timber decking for yourself? At KEKSIÄ, we’ll help you choose the right product for the best result on your project.

To find out more, call our team of experts or fill out the enquiry form on our Contact page.